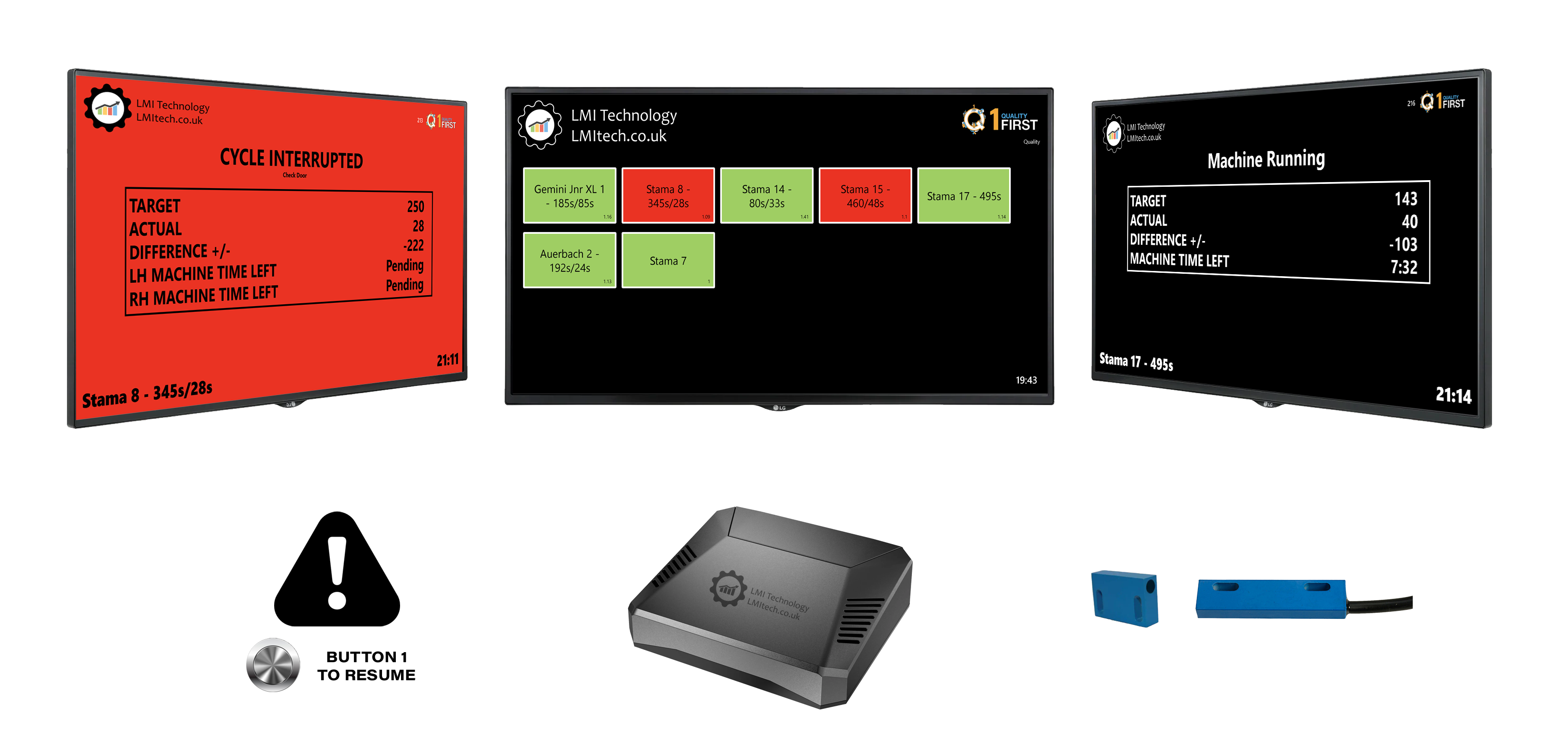

This is our flagship product. We had an enquiry from a large machine shop that struggled to transmit targets, arrange material flow and schedules to the machine centre and so LMI Production assist was born.

In the original design brief we had to come up with a GUI for the operator based on Jidoka techniques that interfaced with the machining centre.

Very quickly a simple specification and solution had been generated but this was only the beginning. We have worked with our customer to add more functionality all of which can be added or deleted remotely using our remote log in system.

Features / options Include:-

- RFID Interface so only approved users can operate the machine

- Show the operator specific data on the parts being made

- Machine Name

- Target and actual parts made

- Time to end of cycle / end of loading

- Different screen colours / combination of colours define different operating conditions:-

- Machine running

- Door open mid-cycle warning

- End of cycle (load unload required)

- End of shift / break

- Material state (running low / run out)

- Planned Downtime

- Help required

- Machine inoperative (maintenance required)

- Show Quality areas to check on parts made

- Help Guides

- Quality Guides

- Remote (in factory services)

- Status screen – single screen in production shows all the information of all the machines of the system in one place

- Materials screen, stores can see a machine is calling for product

- MTBF / MTTR analysis

- Remote (in or out of factory services)

- Handheld phone / tablet licence to see Status screen and data

- Immediate remote email of machine running below a specific efficiency

- Can email EOD/W/M/T data as a CSV or other report format